2022 September the Third Week WSW Technical Knowledge: Super-finishing method on grooved raceway of angular contact ball bearing with two-piece ring

The raceway accuracy of double half ring angular contact ball bearing has reached a high level

Abstract: through the improvement of existing processing equipment and process methods, the raceway accuracy of double half ring angular contact ball bearing has reached a high level.

Key words: angular contact ball bearing with two-piece ring; grooved raceway; super-finishing

1. Preface

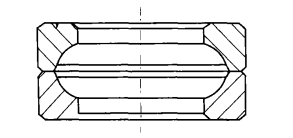

Bearing raceway is the working surface of bearing bearing bearing load, and its accuracy is the main factor that determines bearing performance and service life. Through the research and improvement of the current ultra precision machining method, machining equipment and abrasive of the groove of double half outer ring angular contact ball bearing, the geometry and accuracy of the groove surface are improved and the roughness of the groove surface is reduced. The structure of the half outer ring is shown in Fig. 1.

Fig. 1 double half outer ring of angular contact ball bearing

2. Transformation of process equipment

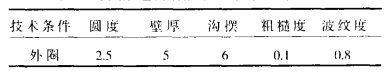

Since the factory does not have special equipment for fine grinding the raceway of this peach shaped half ring angular contact ball bearing, it used to use steel sand as abrasive and felt wheel polishing. After polishing, the raceway surface is bright and beautiful, but it can not improve the geometric error of the raceway surface, and even damage the original geometric accuracy. The product quality cannot guarantee the accuracy of the half outer ring groove after polishing. Take d116205 as an example, as shown in Table 1

Table 1 technical conditions for finishing grinding of outer ring raceway (polishing)

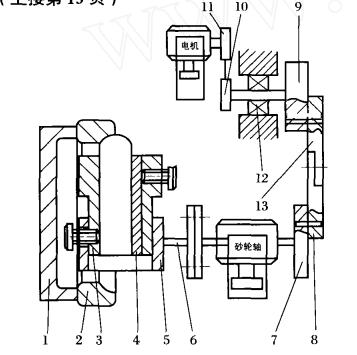

According to the actual situation of the factory, the existing m8820 swing head grinder is modified into a semi outer ring superfinishing equipment. The rotation of the workpiece head frame of the machine tool ensures the groove curvature requirements of the ferrule parts: the key to the problem is the pressure on the groove and the oscillation of the oilstone during the Superfinishing of the oilstone. When superfinishing the ferrule groove of the part, the pressure exerted by the oilstone on the ferrule half groove is bound to generate the axial force component, which makes the ferrule move along the direction of the axial force component, resulting in the failure of superfinishing. In order to solve the above problems and improve the machining accuracy, the original spring chuck is replaced with an electromagnetic centerless chuck to support the workpiece; Secondly, the transmission mechanism is designed to change the grinding wheel shaft into the fine grinding shaft and the oil stone chuck that drive the oil stone to swing up and down, and install the oil stone, as shown in Fig. 2.

1.Washer 2. Workpiece 3. Oil stone clamp 4. Oil stone pressing plate 5. Oil stone clamp sleeve 6. Oil stone sleeve connecting rod 7. Flange 8.13. Eccentric shaft connecting rod 9, eccentric wheel 10.11. Belt pulley 12. Shaft

Fig. 2 oil stone clamp and transmission mechanism

3 Working principle of fine grinding machine

Working process: the rotation of the workpiece head frame of the machine tool ensures the groove curvature of the workpiece channel, and the workpiece shaft drives the workpiece to rotate around its axis through the electromagnetic chuck. In addition, the motor drives the eccentric wheel 8 to rotate through the belt pulley, and the grinding wheel shaft reciprocates through the connecting rods 6 and 7, thereby realizing the whole set of fine grinding action.

The amplitude of the oilstone can be controlled by adjusting the eccentricity, and the swing frequency of the oilstone can be realized by adjusting the motor speed.

The pressure of the oil stone on the channel is to add a compression spring on the oil stone clamp. The pressure can be controlled by the operator on the feed handle of the grinding wheel. If the feed amount is large, the pressure is large, and if the feed amount is small, the pressure is small. This method is also applicable to the Superfinishing of the half inner ring groove of the double half inner ring angular contact ball bearing.

4 Processing technology

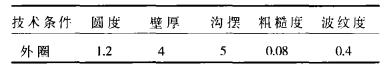

In the process flow, the process of segmented processing is arranged. Firstly, the oilstone with low hardness, small density and large grain size is used for rough machining, mainly to remove the grinding wheel grinding marks left by the grinding wheel grinding, and then the oilstone with small grain size is used for fine machining with low pressure, so as to reduce the roughness and waviness of the processed surface. Generally, M10 or M14 cubic silicon carbide oilstone is used for coarse super. Jingchao generally uses M5 or M7 cubic silicon carbide oilstone, and the lubricating coolant is mixed with 85% kerosene and 15% No. 30 engine oil. The accuracy of d116205 outer ring after processing is shown in Table 2.

Table 2 technical conditions for fine grinding of outer ring raceway (oilstone)

5 Conclusion

At present, the processing technology and the modified process equipment of the semi ring angular contact ball bearing raceway have been continuously improved in the production process, which has significantly improved the quality and production efficiency of the three and four point angular contact semi ring ball bearing produced by the factory.

More about WSW Angular Contact Ball Bearing:

WSW excellent quality Angular Contact Ball Bearing with reasonable price for customers all over the world and can produce various types of bearings,over 200 series and 5000 specifications or so. Angular contact ball bearing can bear radial load and axial load at the same time. It can work at high speed. The larger the contact angle, the higher the axial bearing capacity. The contact angle is the angle between the connecting line of the contact point between the ball and the raceway in the radial plane and the vertical line of the bearing axis.

https://www.wswbearings.com/products/Deep-Groove-BallBearing/889.html

WBM are professional Angular Contact Ball Bearing manufacturers and suppliers in China, with bulk high-quality products in stock. If you are going to buy a customized taper roller at a competitive price, welcome to get a quotation from the WBM factory. In line with the business philosophy of pursuing excellence, continuous improvement and common prosperity, the ball header, solid steel balls, roller header produced from WBM is absolutely high-quality and inexpensive.