WSW Technology Knowledge: Mass calculation of crown plastic cage of deep groove ball bearing

Analyze the theoretical research and production application of bearing heat treatment technology at home and abroad

With the development of technology, crown type plastic cages of deep groove ball bearings are more and more widely used. At present, the design and manufacturing technology of this kind of cage has become mature, but there is no formula that can be used to accurately calculate its quality. This paper will give its calculation method for reference in cost accounting, injection mold design and injection molding machine modeling.

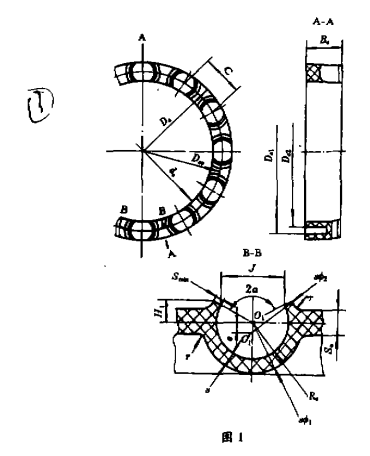

The structure and relevant dimensions of this cage are shown in Figure 1.

Figure 1

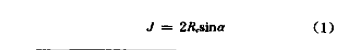

In the design, if the chamfer line at the lock of the ball pocket passes through the spherical center of the inner ball pocket, the design and calculation workload will be simplified.

This is consistent with the current design method. If the value of J is too large, the amount of lock is too small. When the cage works, the material changes due to temperature rise, and the size expands, it may be thrown out; If the value of J is too small, the resistance of forced demoulding and assembly is too large, which is not conducive to demoulding and assembly, and whitening may occur at the same time.

Figure 2 shows the magnifying ring of the ball pocket lock in Figure 1, which can be obtained from Figure 1 and Figure 2

Figure 2

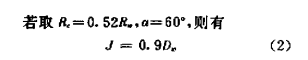

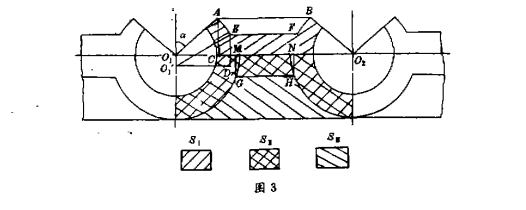

Unfold the cage along the diameter of the center circle of the ball pocket, as shown in Figure 3

Figure 3

If it is considered that the inner ball pocket and the outer ball pocket are cylindrical after being expanded, the volume of the cage is

If its density is p, then its mass is

M=VP

For GRPA66-25, cage P is generally taken as 1.4 × 10-8 kg/mm3. The quality error calculated by the above method generally does not exceed ± 5%. The error mainly comes from the density difference of materials and the density difference of finished products caused by the change of injection conditions.

More about WSW Deep Groove Ball Bearing:

Deep groove ball bearings are the most widely used bearing type and are particularly versatile. In structure, each ring of deep groove ball bearing has a continuous groove raceway with a cross section of about one third of the circumference of the ball. It can bear certain axial load and radial load. When the radial clearance of the bearing increases, it has the property of angular contact ball bearing and can bear the alternating axial load in two directions. Low friction and high speed. Simple structure, low manufacturing cost and easy to achieve high manufacturing accuracy. Generally, stamping wave cage is adopted. For bearings with inner diameter greater than 200mm or high-speed operation, turning solid cage is adopted.